Belt Conveyor

View Products

Bucket Elevators

View Products

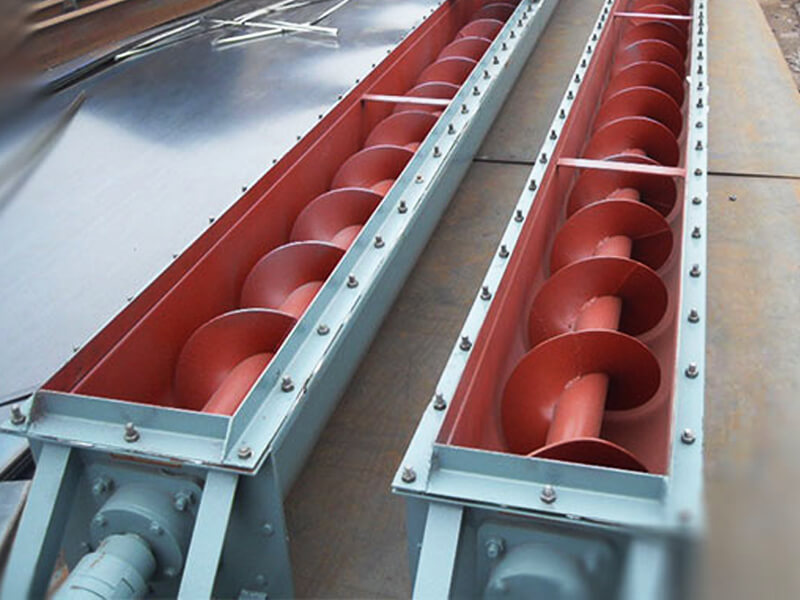

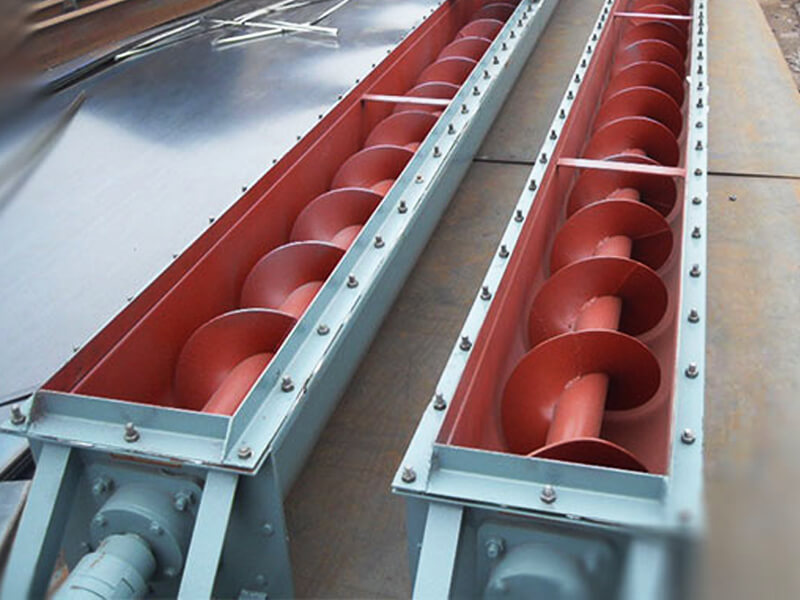

Screw Conveyors

View Products

Bag Stacker & Truck Loaders

View Products

Coal Handling System

View Products

Material Handling Products

View Products

Our range includes Belt Conveyors, Vibrating Screens, Coal Crushers, Complete Coal Handling Equipments, Impact Idlers, Carrying Idlers, Drum Pulleys, Gravity Roller Conveyor, Packaging Conveyor, Bucket Elevator, Hydraulic Cylinder and Portable Belt Feeders. These are manufactured using high grade raw material and cater to the needs of various industries such as food processing, dairy, cellulose and pharmaceutical.

Fill the below form and our sales team will take time to understand your application and give you the necessary pre-sale advice to help you get the right products the first time round.

We provide efficient and robust solutions for various industries. Our professional team works to increase productivity and cost effectiveness on the market

Call 98988 16756 Get a Quote